Bolstered by nine Park Industries® machines, including three different types of sawjets, Jason Borden of Chivino Surfaces has seen consistent growth in their production, without the need to grow their labor force at the same rate. Machine uptime is key for Jason and he understands Park Industries® is unmatched in this important aspect.

Chivino Surfaces

Since 2003, Chivino Surfaces has been fabricating stone. A family-owned business, they have evolved from working primarily with builders to working almost exclusively with box stores like Home Depot and Lowes. An integral part of their evolution was their willingness to go digital.

Today, with fifty employees (about 15 in the fab shop) and nine machines, this all-Park shop has an impressive story of transformation and change beginning in 2014 with a visit to a Digital Stoneworking Expo™ and the purchase of their first CNC sawjet.

Read their story! Expand the sections below to learn more about Chivino’s story and their partnership with Park Industries®.

Fabricating in The Valley of the Sun

Treat ‘em Like Family

Jason Borden has always believed in producing the best product possible and adhering to the philosophy that you treat your customer like you’d treat your family. Since 2006, Chivino worked primarily with builders. During the recession, their customer demographic changed, evolving more to commercial work. In time, they earned a reputation for producing a quality product and working well with retailers. Today, their clientele includes major retailers like Lowes, Floor and Décor, Cabinets to Go, IKEA, and, most recently, Home Depot. It was a defining moment for Chivino and one they’re very proud of.

What’s in a Name?

Often mistaken for Spanish or Italian, the name Chivino actually has its roots in… alcohol. In 2005, while enjoying the company of his wife and parents, Jason was having a glass of wine and his father was drinking a scotch. Chivas Regal to be specific. Brainstorming ideas for the company’s name, Jason’s wife, suggested they use a blended name that references the two drinks of choice, and Chivino was born. Initially, the name wasn’t intended to be the front name of the business, but it was catchy, and it stuck. So, while it’s not in any dictionary, it is memorable and makes for a great story.

Going Digital

Making the Leap

In 2005, Chivino began their relationship with Park Industries® when they purchased a VELOCITY® [Decorative Edge Polisher]. They remained a manual shop until 2014, when they made the decision to go digital. Jason wanted something that would separate him from the competition, and believes that if you don’t innovate, you’ll be passed up. Looking to satisfy both, he attended a Digital Stoneworking Expo.

“If you want to be a major player, you have to be automated. You’re never going to be a major player if you’re manual.”

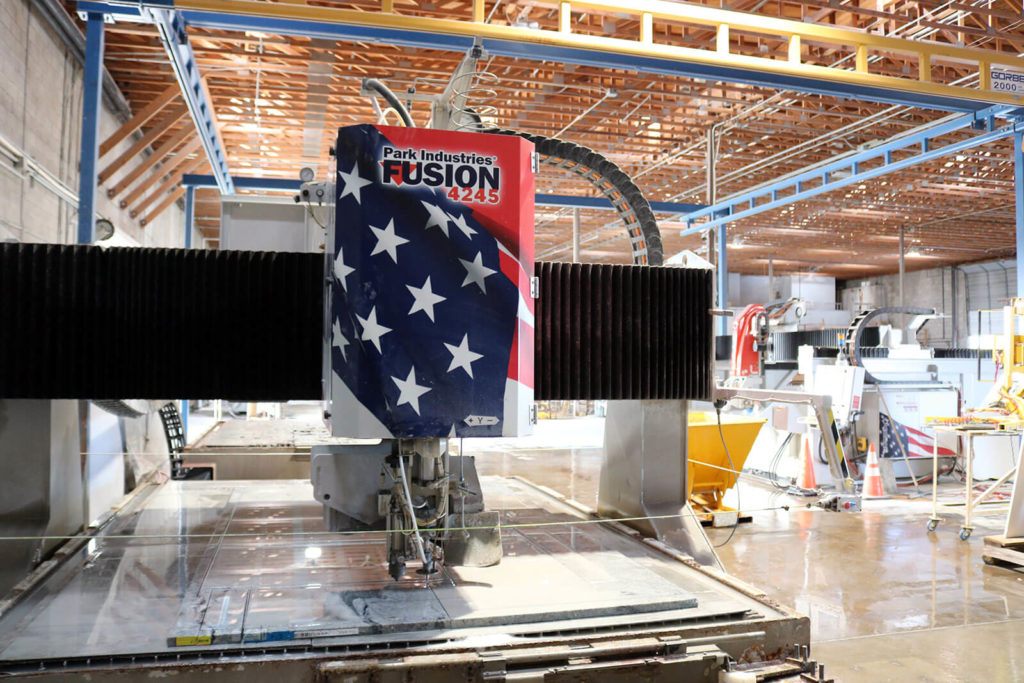

Partnering with Park Industries was an appealing prospect for Jason, placing value on Park’s reputation and their focus on customer support. He bought his first FUSION® [CNC Sawjet] after the DSE and although he had a lot to learn about digital fabrication, he had the right foundational elements and a good partner.

By the Numbers

Since that first DSE, Chivino has fully embraced digital fabrication, and now has nine machines, with the SABERjet™ and OPTIMUS™ Sawjet, as well as two TITAN® CNC Routers all added in the last year. When asked about the benefits of moving to digital, Jason responded in terms of comparatives. What Chivino is able to produce today with Park’s machines and 15 shop employees would take a hundred men if he were still manual.

“What the digital equipment allows you to do in the amount of footage you can do with the amount of men that you need is unmatched.”

Another benefit is in the employees needed to run production. Going digital shifts the skillset from craftsmen and tradesmen to loaders, unloaders, and machine operators. You still need people who take pride in the product and care enough to want it to be perfect, but the skills you’re hiring for are very different and much easier to find. Craftsman needed for the manual process of the past, Jason explains, are pretty much nonexistent for hire in their market.

A Word of Advice | Take the First Step

If there’s one thing that his experience in going digital has taught Jason, it’s that you need to continue to innovate and stay ahead of your competition. To anyone who hasn’t gone digital, Jason encourages small steps forward. It doesn’t need to be a giant plunge into digital fabrication, rather start small. Make one investment in one saw.

“At the end of the day, I don’t know a digital shop where [going digital] didn’t change their life.”

Why Park?

Machine Uptime Over Everything

Jason knows the key to profitability is to keep cutting. Machines sitting idle waiting on a part cost him money, cause the stress of playing catch up, and are something he wishes to avoid as much as possible. This is why he continues to choose Park Industries® for his machinery needs. Their customer service simply delivers.

Jason states, ” When I am cutting 30 slabs a day, I cannot afford for my machines to be down…it’d be a huge cost for my business. What separates Park Industries® from the rest, is they make sure my machinery will not stay down. Their customer service is great and I can get a part here by 10am the next morning 99.9% of the time.”

He concludes, “Chivino couldn’t be here today without Park Industries® equipment. I’m proud to say that I’m 100% Park Industries®.”

QUICK FACTS

LOCATION

Mesa, Arizona, USA

TYPE OF FABRICATION

Stone Countertop

WEEKLY PRODUCTION

3750 – 4500 sq. ft. per week

NUMBER OF EMPLOYEES

50 total (15 in fabrication shop)

PARK EQUIPMENT

SABERjet™ CNC SawJet, OPTIMUS™ Robotic Sawjet, FUSION® CNC Sawjet, TITAN® CNC Router (x2), VELOCITY® Edge Polisher, FASTBACK® II Edge Polisher (x2), Pathfinder® Digital Photo Station

PARK PARTNERSHIP

Began in 2005 with a VELOCITY®.