Proudly family-owned for 42 years, Mette’s Custom Countertops (MCC) has a long history of delivering outstanding experiences to its customers with the help of their several Park machines.

Mette’s Custom Countertops

With their origins in cabinets, Mette’s began fabricating countertops in 2006 with a Park Industries saw as their very first machine. Alan Mette, the owner of MCC, was very impressed with Park Industries® after touring their facility and seeing their USA manufacturing process. Alan found Park’s full package of quality machinery, excellent service, and an unmatched dedication to partnership.

Read their story! Expand the sections below to learn more about their story and partnership with Park Industries®.

New Stone Shop Expansion

In 2021, Mette’s business was exploding, the shop was running out of space, and production couldn’t keep up. Alan’s first step was to call Park to develop an expansion plan. His sales consultant walked through every aspect of building a new shop from drainage to cranes and staging areas. Park’s sales team worked with Alan to lay out the shop for production, and efficiency, and fit the lot perfectly.

Adding three new Park machines

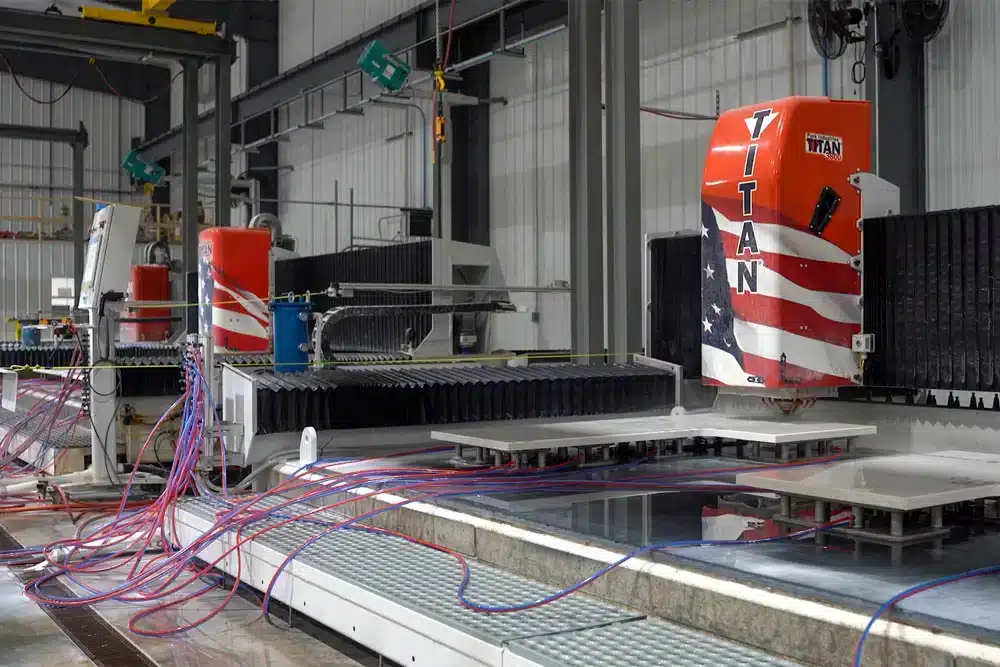

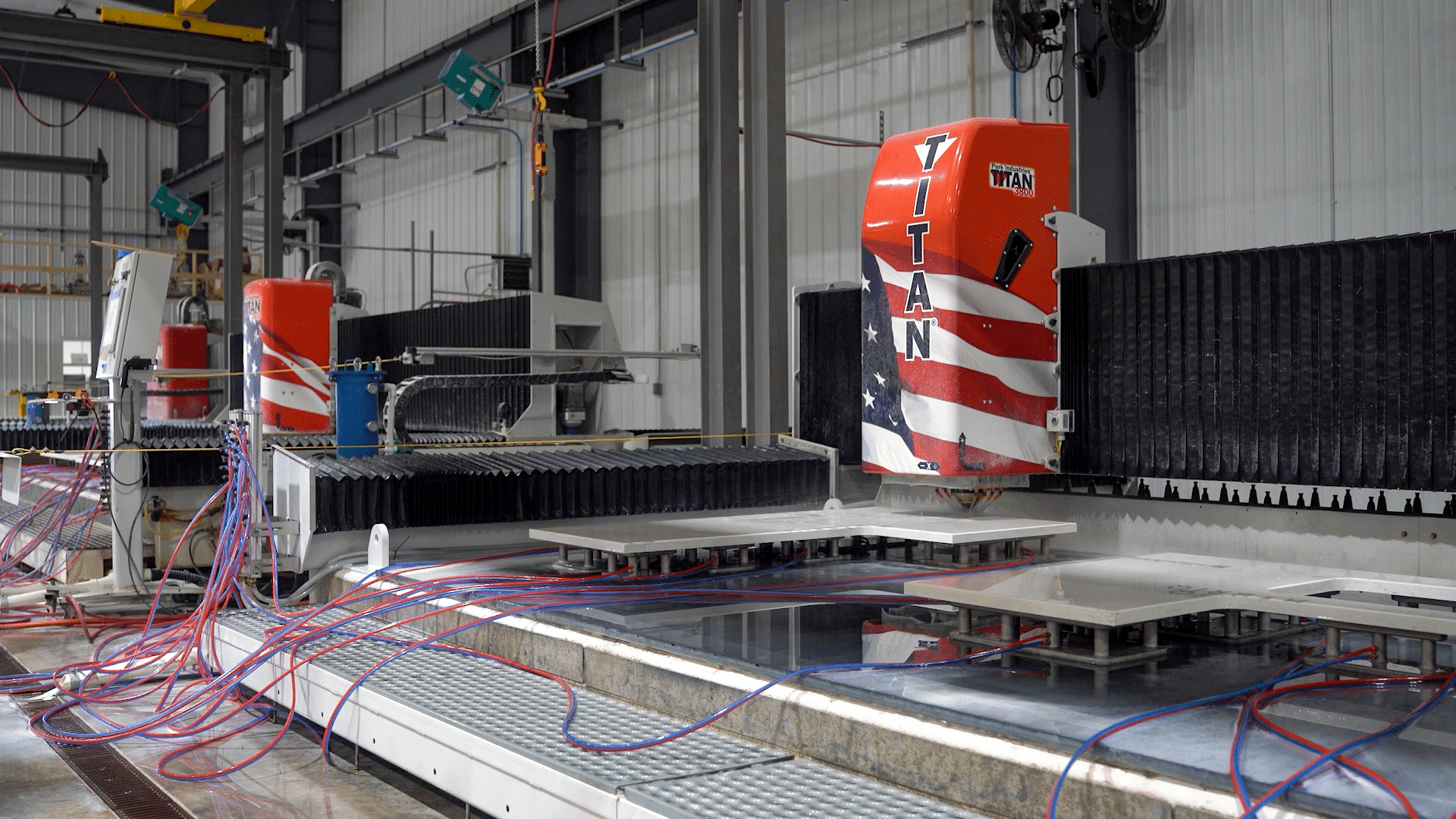

The 130 ft x 175 ft stone shop addition was completed in the Fall of 2022. New, state-of-the-art machines were added including the TITAN® 3800, a two-table SABERjet™ XP, and the HydroClear™ Pro 400. Park brought over and reinstalled all their existing machines (4) as well. They got them moved, provided machine health check care, and had them making mud again in less than a week.

The brand-new shop is extremely organized, lean, and productive. It even includes an indoor slab viewing area that is climate-controlled and well-organized. It provides a better experience for customers and employees alike.

Alan shares, “I couldn’t have executed this expansion without Park – they were instrumental from day 1. They got it exactly right, I wouldn’t change anything.”

The Machines

SABERjet™ XP

The cutting speed and efficiency the SABERjet™ XP has provided MCC has been monumental and is providing them plenty of room to grow into its full capacity. The two-table design eliminates loading time since they can cut on one table and offload/load the other.

Alan expands on features of the SABERjet XP that have been making a strong impact for them, “The miterjet feature is great and helps us efficiently tackle any intricate miter work that we didn’t offer before the SABERjet XP. Now we say bring it on to miter work. We have also been utilizing the bigger horsepower to speed up cuts and tackle any material efficiently.”

TITANs

Alan has one of each TITAN® generation in his shop: 1000, 2000, and 3000. His army of TITANs delivers high-production polishing. The large, heavy-duty tables provide the freedom to load up a full table, hit go, and walk away while it efficiently finishes countertops. The three workhorse TITANs operating at full tilt have given production wings to soar to new heights.

HydroClear™ Pro 400

During the transition into the new shop, Mette’s chose the HydroClear™ Pro 400 model and it handles managing the water to and from their fleet of equipment with ease. All their CNCs are running high flow water speeds since the 400 is fully capable of this output. Alan shares, this alone has increased their production by 20%. They can even wash the floor down in seconds with a 2” fire hose thanks to significantly increased water pressure throughout the shop.

Alan shares, “The water quality is superb! All of our CNC routers and saws have water filtered down to 5 microns. We have never had to replace a filter. With our old system, we had to replace the filter every 3-5 days.”

The addition of the pit stir system has protected Mette’s Cabinets & Countertops employees from the nightmare stories of needing to clean pits. They will never have to get in the pit again with the HydroClear Pro 400. Alan shares that they checked the pit once after 3 months just to see and it had zero solid build-up in it.

Alan proudly states, “We now recycle 100% of our water, which is a big deal for us since we use around 80,000 gallons per day. This system delivers two major benefits for us: Our shop is extremely environmentally friendly and the savings on our water bill have provided a huge boost to our bottom line.”

Results

The new building and addition of new machines have more than doubled MCC’s capacity. Alan shares proudly there are no more late nights in the shop, which has led to more family time and less overall stress of running the business.

Alan states, “The expansion has allowed us to create a safer and more enjoyable work environment for our employees, our number one asset.”

The refined layout has helped their flow and gained them increased efficiency. With a 15% increase in production and a 14% decrease in labor, Mette’s Cabinets & Countertops has dropped 54% reduction in overtime just in the stone shop – they are excited to see those numbers as a direct result of their recent changes.

Why Park Industries®

At Mette’s Custom Countertops, they are proud to show off their USA machines to their customers. Park Industries is more than an excellent machine manufacturer – Park is a company they view as a true partner of their business. Alan shares that he can rely on multiple people on the Park team for assistance whether it’s to do with service, sales, or training.

Alan shares, “Park provides service, service, service. We have many examples of Park going the extra mile for us. Park employees have worked after hours to get us parts for the next day. Park has never let us down and always takes care of us.”

QUICK FACTS

LOCATION

Effingham, IL, USA

TYPE OF FABRICATION

Countertop

PARK EQUIPMENT

SABERjet™ XP Two Table, TITAN x 3, FASTBACK II, FUSION, HydroClear PRO 400, Pathfinder

PARK PARTNERSHIP

Began in 2006 with a YUKON® Bridge Saw

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.