With a focus on the small town values of “family, quality, and service”, Oskar and Courtney Gruber of Chippewa Stone have found the right fit for their machinery partner. With their new Park Industries® CNC machinery and the support that comes with it, they’ve been able to efficiently meet their market’s fast-growing demand.

Chippewa Stone

Courtney and Oscar Gruber founded Chippewa Stone in 2004, at first as a one-stop home remodeling business who outsourced their stonework. In 2008, they began cutting and fabricating stone themselves, eventually focusing solely on what they did best: stone fabrication.

Read their story! Expand the sections below to learn more about their story and partnership with Park Industries®.

More Than Just a Sale

First Park Machine

Nearly a decade after Chippewa Stone started cutting their own slabs, Oskar and Courtney decided they had enough of the service they were putting up with for their bridge saw at the time. Oskar explains, “The previous company we purchased from were great…right up until the machine was installed. After that we never heard from them and getting service felt like we were being an inconvenience to them.”

The Gruber’s heard good things about Park Industries® and loved the fact that Park is both family-owned (Courtney refers to Park as “family-owned company on steroids”) and Made in America. In June of 2018, they installed a YUKON® II Bridge Saw.

After the machine was installed, Oskar was happy to receive a different experience this time around:

“Once Dale, our sales consultant from Park, sold us that saw he continued talking to us and asking how he can help. Even with things like the flow of the shop and finding ways to improve material handling efficiency. He had the sale and could’ve moved on, but he’s stayed committed with us as in an advisor role.”

Going Digital

After numerous recommendations by Dale – Courtney, Oskar, and their shop manager Dan went to the Chicago Digital Stoneworking Expo in 2019. This opened up their eyes to the possibilities of going digital.

Oskar reflects on the event, “Great event. I loved it. Seeing other shops and talking to other owners was a huge help with finding solutions to common problems in the industry.”

Courtney continues, “There were shops who went digital producing numbers similar to ours in much smaller facilities. We have a pretty large facility, so I thought if they can fit in that machinery and excel, then we can do it too.”

Digital Sawing & Edging Upgrades

SABERjet™ XP

With the guidance of Park Industries® and Dale, Chippewa Stone added a SABERjet™ XP CNC Sawjet to take over their shop’s cutting production in June of 2020. Oskar said the capabilities of the new machine were extremely evident as he watched it cut a commercial job for them.

“This machine has given us the ability to take on commercial work. We cut 8 bathroom vanities on the table and the SABERjet™ XP had it all done in under 45 minutes. That would’ve taken us all day prior to it. The waterjet is a game changer and I love the way the machine runs.”

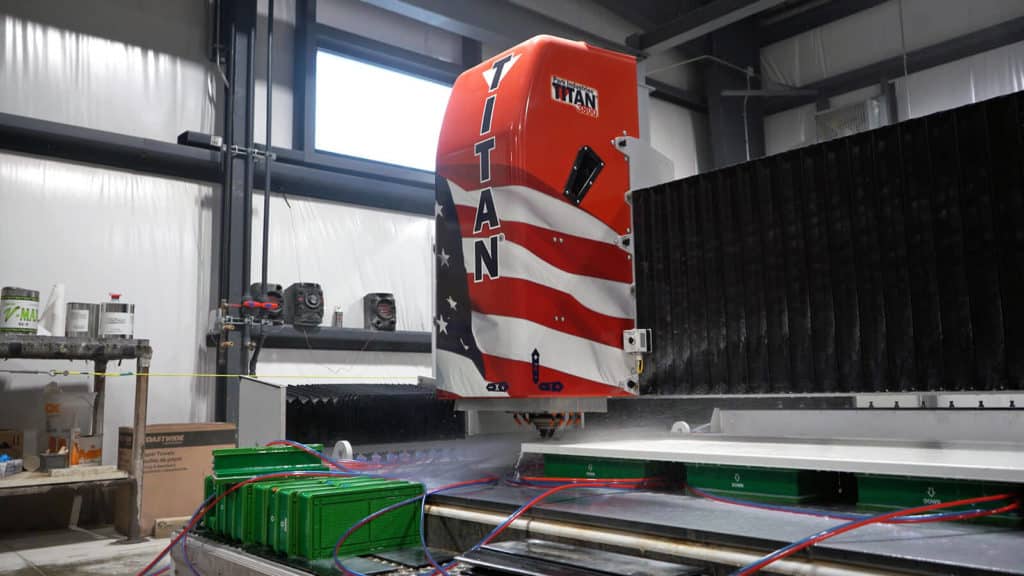

TITAN® 3800

Soon after, Chippewa Stone was looking to add a boost to their polishing production. In December of 2020, they installed the industry’s leading CNC router – the TITAN® 3800. The quality of the polish, speed of the machine, and freedom it gives their fabricators are the benefits they find most valuable.

Oskar states, “I prefer to run all my Quartz on the TITAN® – you get a better polish. And being able to load up that large table with big islands or full jobs on the TITAN® it’s getting them done faster and freeing up my guys to do other jobs. Everything is just getting done quicker and more efficiently since adding it.”

Finding the Right Partners

By choosing machinery from the industry-leader, Chippewa Stone was able to tap into Pak Industries® network of partners. From laser templating, through financing alternatives to business software, Oskar and Courtney were able to rely on trusted industry partners for their business.

Chippewa Stone has established a great relationship with Jim Gahan of MFS (Manufacturing Finance Services). Fabricators choosing this form of capital equipment financing, are able to use the machine as collateral keeping credit lines open for other areas of business. Since it is still a conventional loan, they are able to reap huge tax advantages with section 179 of the tax code, and are able to write off up to the full price of the machine.

The Results

The Right Machines at the Right TIme

Chippewa Stone has faced record sales over the last half year. Courtney reflects on their decision to invest in machinery when they did, “It’s like everyone spent quarantine looking at their kitchens and saying I am done with this. Since things I have started to open up, we have been packed. I don’t think we would be able to keep up with the demand, had we not made the decision to get the machinery when we did.”

Oskar continues, “We are very grateful for the numbers we’ve experienced, but there’s no way we would’ve been able to keep up. We would’ve had to been working nights, weekends, pretty much all the time and it would’ve been unfair to put that much stress on the guys in the shop. To be able to produce that much more, without adding labor hours or pushing deadlines way out is a testament to the efficiency of the machinery!”

Courtney concludes, “Those machines are paying themselves off quickly.”

Final Recommendation

Why They Recommend Park Industries®

The core values of family, quality, and service stand out to Courtney and Oskar. They feel as if Park Industries® aligns well with them in those areas and appreciate the partnership between the two companies.

On the customer service they’ve received, Oskar states, “I would say customer service is one of the biggest reasons why Park Industries® stands out. We’ve never in the history of our company canceled on an installation. Park gives me confidence that they will keep us up and running. Park is on the higher end machinery, but I don’t mind paying it if I know I can get parts and phone support. The whole experience has been great.”

Courtney leaves those who may be on the fence of making the investment a strong statement, “Park Industries® makes you feel comfortable investing based upon how you are treated along the way and the results you get at the end.”

QUICK FACTS

LOCATION

Medina, Ohio, USA

TYPE OF FABRICATION

Countertop

WEEKLY PRODUCTION

2,500+ sq. ft. per week

NUMBER OF EMPLOYEES

7 in Fabrication Shop

(2 operators, 5 polishers)

PARK EQUIPMENT

SABERjet™ XP CNC Sawjet, TITAN® 3800 CNC Router, YUKON® II Bridge Saw, Pathfinder™ Digital Imaging System

PARK PARTNERSHIP

Began in 2018 with a YUKON® II Bridge Saw.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.