VELOCITY®

Decorative Edger

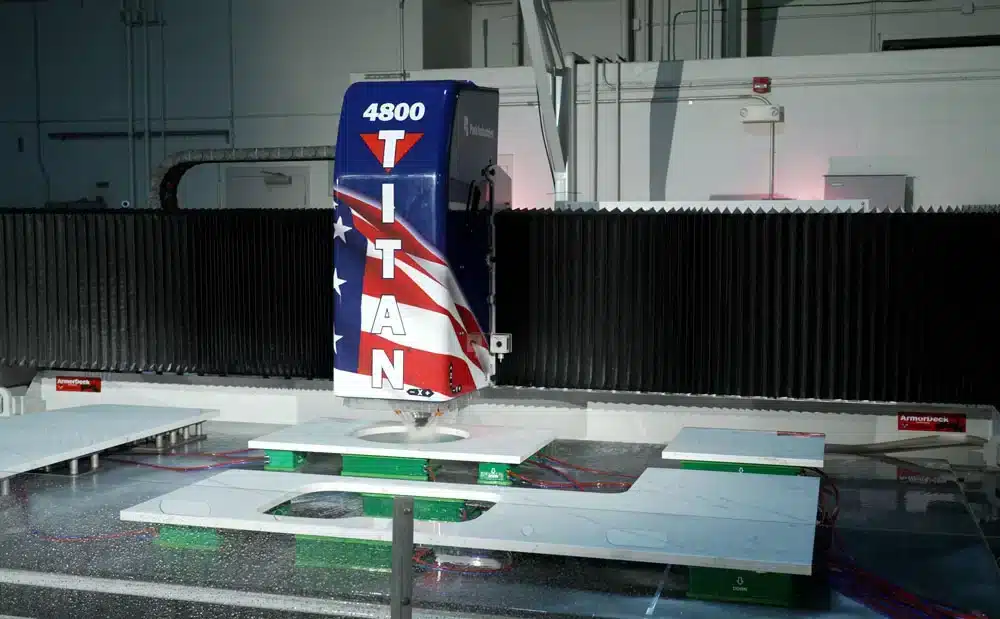

The VELOCITY® Edge Polisher gives a single operator complete control for finishing high-quality edges on pieces up to 12 feet long. Park’s smartspindle technology and tool-stagger programming polishes top and bottom edges in one pass to save you material handling, manual labor, and valuable time.

Single Pass

PolishingHigh Production

Decorative EdgesCOUNTERTOP

FABRICATION

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Maximize Productivity

- Decorative edge shaping and polishing for speed and precision

- Pre-programmed profiles for a variety of shapes

- Easy-to-use touchscreen controls

- French euro miter friendly cuts

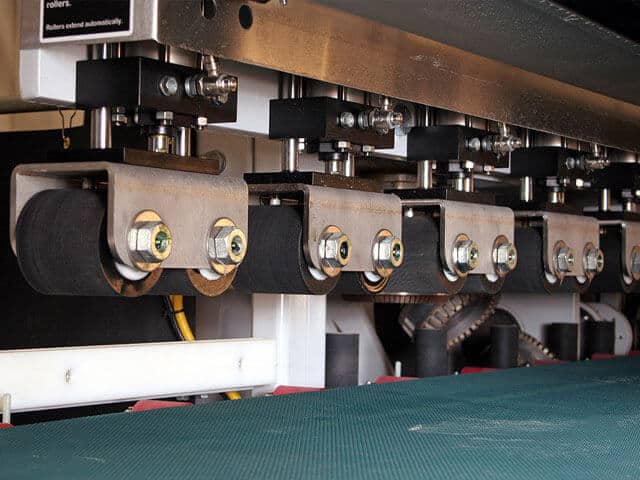

- Precision slide bed under main drive offers better reliability than roller systems

- Tile jig for running 1 cm tile (optional)

- User-Friendly

The user-friendly touchscreen allows for quick adjustments for stone thickness, conveyor speed, and spindle staggers. The controls also give an operator the ability to easily make profile changes without any tools.

- Exclusive ArmorShield Protection

The ArmorShield Protection is a process that protects critical machine parts which enhances corrosion and wear resistance.

It extends the lifespan of critical components by protecting the parts from the harsh, wet environment, increasing machine uptime.

The ArmorShield is not a plating or surface coating process. This unique process produces an aesthetic black finish that impregnates the material for strength and durability. The treatment actually changes the composition of the material on the outside of the part.

Specifications

| Select up to 3 models to compare key specs | VELOCITY®View Layout Drawing | |

|---|---|---|

| Number of Passes | Single Pass | |

| Edge Types | 70 Repeatable Edge Profiles (Flat, Radius, Decorative) | |

| Number of Spindles | 12 | |

| Polishing Speed | 12" - 24" per minute (dependent on edge) | |

| Material Handling | Swing Out Conveyor + Infeed / Outfeed Conveyors | |

| Part Orientation | Horizontal | |

| Part Thickness | 2-6 cm | |

| Part Length | 24" - 144" | |

| Part Width | 4" - 144" | |

| Radius Capacity | Up to 3" | |

| Weight | 17,000 lbs. |

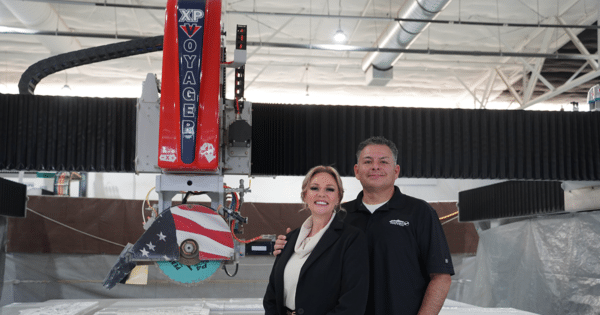

The Velocity has given me about 70 different edge profiles which allows me to cater to the more detailed customer and achieve a huge increase in productivity!

Yes, I recommend this product.

The Velocity is a stone-eating machine. This machine will bring your productivity to a whole new level and propel you in a new league of fabrication.

Yes, I recommend this product.