For our next Cut This, Polish That, we tackle a challenge presented by a fabricator who suggested we cut and polish a Euro seam countertop using just the VOYAGER XP and FASTBACK II, and how fast will they do it.

Join Rocky and Jesse from Park Industries® as they guide you through the programming, cutting, and edging process of an “L piece” with a flawless Euro seam. Witness the results in terms of both efficiency and quality.

What to look for in this Countertop challenge

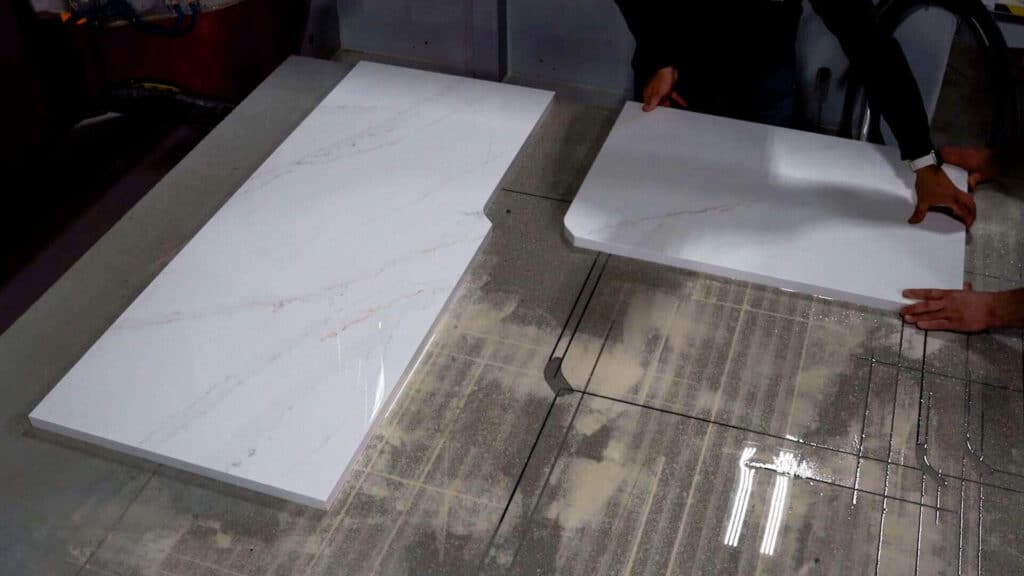

Euro seams typically require hand labor or a CNC Router to achieve a precise edge and tight fit. However, the VOYAGER XP CNC Saw can swiftly cut these parts, making them ready for polishing straight from the saw table. Its TightCut blade plunging feature and routing capability work harmoniously to create seamless transitions from tool to blade, ensuring accurate veinmatching and tight cuts that fit snugly together.

Once cut, the FASTBACK II Edge Polisher, often thought of as just a backsplash machine, showcases its ability to polish countertops as well. With the innovative Polish Offset Pro feature, you can utilize the flat-edger for pieces with seams. This feature precisely instructs the machine on when to engage or disengage the polishing heads with the stone, guaranteeing a world-class polish from the FASTBACK II without any risk of damage to the part. Moreover, the SlabBACK support system provides a safe environment for running large parts.

How to program euro seams on your CNC saw

Join Dan Anderson, a Park Industries trainer, as he takes you through a step-by-step tutorial on programming Euro seams on your CNC saw in alphacam CAD/CAM software. Watch the informative Did You Know? with Dan Anderson guide and discover the secrets to programming flawless Euro seams.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.