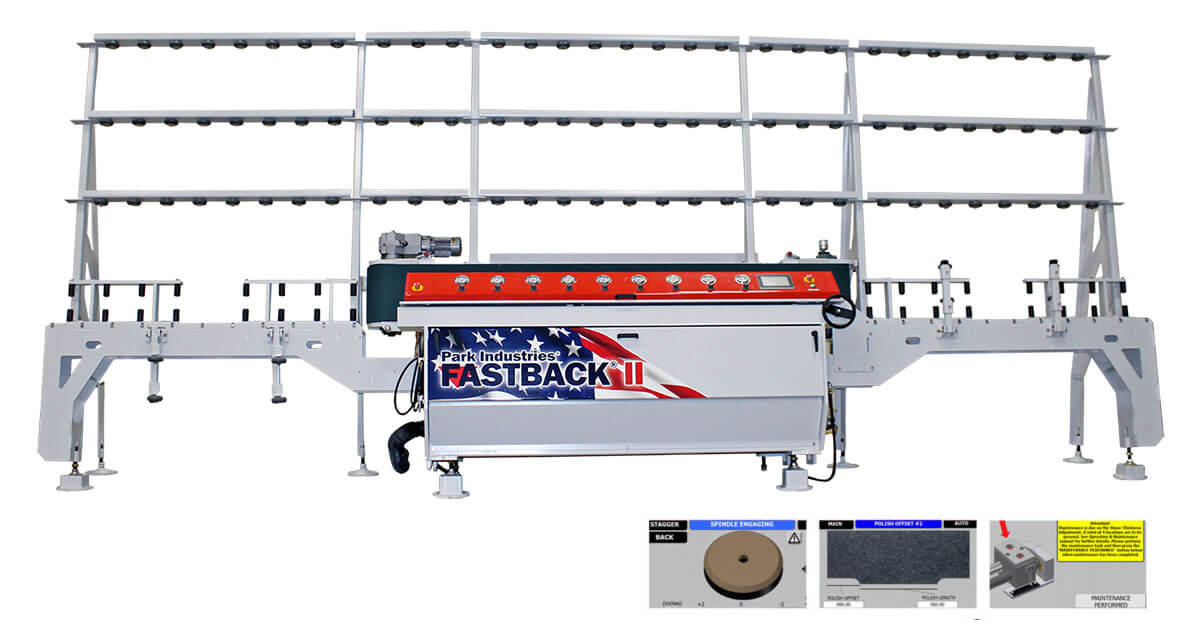

FASTBACK® II

Flat-Edge Polisher

The FASTBACK® II will edge, polish and chamfer backsplash, vanities, and countertops in one single pass. Get exceptional, quality edges at a rate up to 65 IPM and pieces up to 96″ tall with the SlabBACK Support System. This proven workhorse of the stone countertop fabrication industry is the only of its kind completely built in the USA.

SPINDLE

STAGGER65 IPM

SPEEDSINGLE-PASS

POLISHING

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Single Pass, Load-and-Go Automation

- FAST Production: Up to 65″ per minute single pass performance (dependent on material and piece size)

- 45 degree chamfer top and bottom edge corners (removes saw chips)

- Piece height: 3″ to 96″ (with optional SlabBACK™ support system)

- SlabBACK Material Support System

Designed with fabricator feedback, this optional system will provide you the capability of running larger pieces through the highly productive FASTBACK®. Safely secured to the machine and floor, the SlabBACK can manage large pieces up to 96 inches and can be retrofitted to FASTBACK® and FASTBACK® II models with a 10-foot ceiling height requirement.

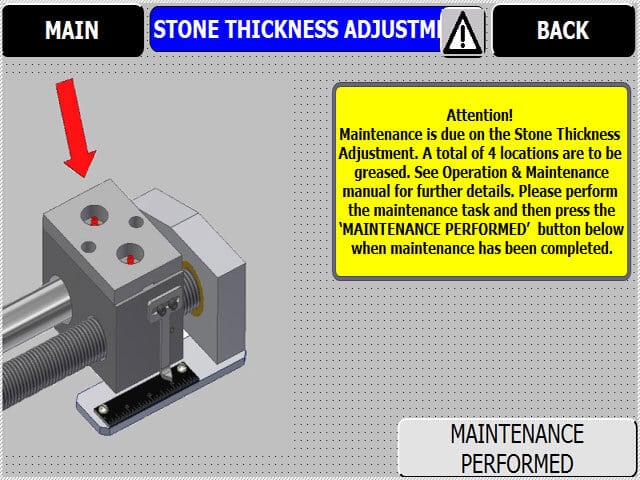

- The Smartest Edger on the Market

The FASTBACK® II is the only machine in its class to offer a programmable, color touch-screen for simple machine controls and useful features including:

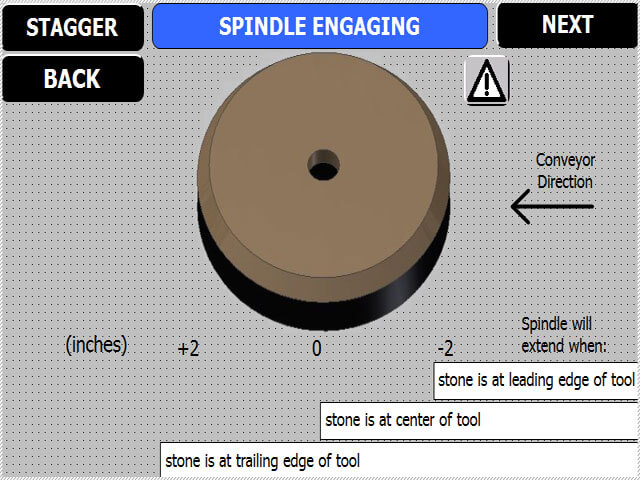

- Spindle Stagger

- Tool Life Monitoring

- Polish Offset Pro

- Automated Water Control/Shutoff

- Manual Spindle Pressure Adjustment

- Remote Diagnostics

- Exclusive Spindle Stagger

Park Industries® exclusive Spindle Stagger on the FASTBACK® II Edge Polisher feature allows the operator to adjust the point at which the tool engages and disengages with the leading and trailing ends of the material. This ensures consistent and total polish end-to-end, essential for tightly nested slab layouts.

- Polish Offset Pro for Euro Seams

The FASTBACK® II Edge Polisher’s exclusive Polish Offset Pro feature allows you to offset the point at which the spindles engage and/or disengage with the material. This allows the operator to run Euro Seam pieces through the machine.

- Optimized Oscillation

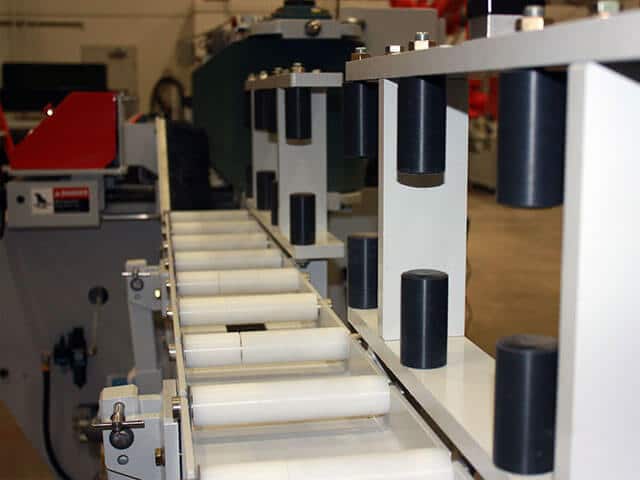

The FASTBACK® II Edge Polisher’s unique oscillating bridge design ensures higher overall polish quality. It utilizes the optimal amount of oscillation necessary to provide excellent polish quality with the least amount of gap possible. This provides a better “end to end” match up with material processed on a CNC router.

- Exclusive Armor Shield

A variety of components on the FASTBACK® II, including the conveyor drums and spindles, are impregnated with Park’s exclusive Armor Shield Protection. The Armor Shield Protection protects critical machine parts by enhancing corrosion/wear resistance.

Specifications

| Select up to 3 models to compare key specs | FASTBACK® IIView Layout Drawing | |

|---|---|---|

| Number of Passes | Single Pass | |

| Edge Types | Flat-Edge with Chamfers | |

| Number of Spindles | 9 | |

| Polishing Speed | Up to 65" per minute | |

| Material Handling | SlabBACK Support System + Infeed / Outfeed Conveyors | |

| Part Orientation | Vertical | |

| Part Thickness | 1-6 cm | |

| Part Length | 16"-144" | |

| Part Width | Up to 96" (Standing Up) | |

| Radius Capacity | NA | |

| Footprint including clearance (L x W x H) | 23'8" x 9'6" x 10' | |

| Weight | 6,000 lbs. |

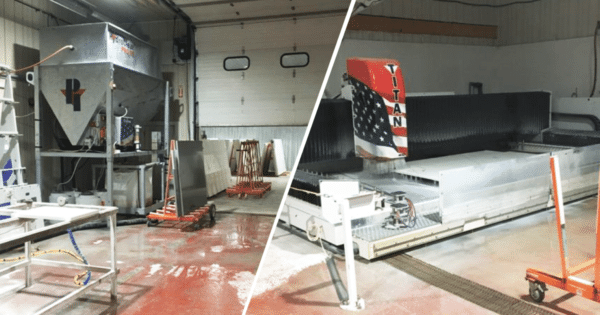

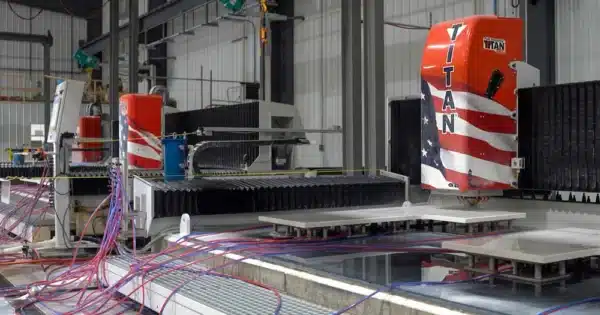

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.

This is an amazing machine – it cuts down on labor times and the final polishing is better than anything we have seen on the market!

Yes, I recommend this product.