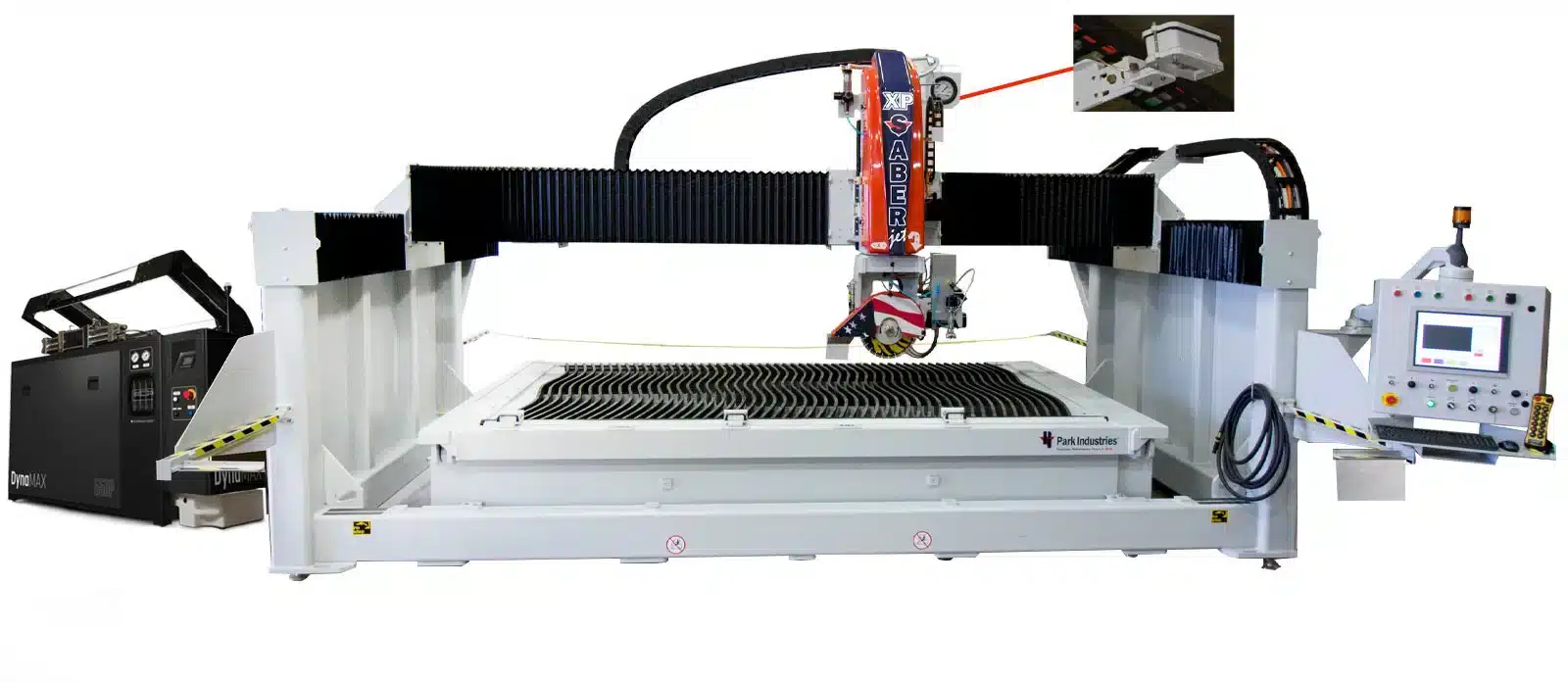

SABERjet™ XP

CNC Sawjet

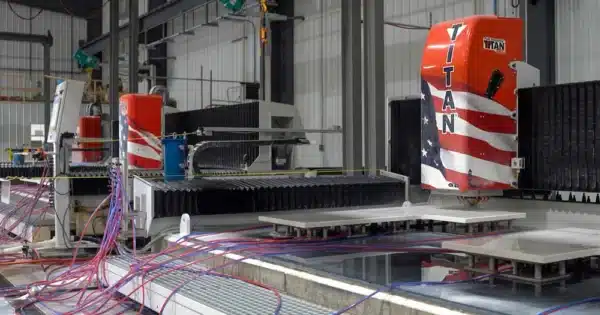

Power up your production with the SABERjet™ XP CNC Sawjet, which boasts an industry-leading 27 hp arbor motor and versatile 5-axis waterjet capabilities. Optimized to cut any material (porcelain, quartzite, and more) with ease. The SABERjet™ XP stands out with its ability to do it at all with maximum efficiency.

High-production processing? No problem. Custom work? You won’t find a more capable mitering machine, with the SABERjet™ XP’s ability to miter with both the blade and waterjet. A true stone-cutting beast!

27 HP ARBOR

SAW MOTOR5-Axis

WaterjetSLAB LOADER

Patented Design

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Power Up With XP

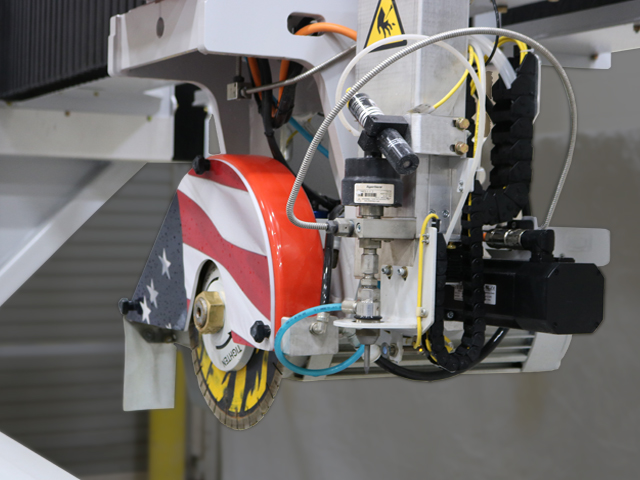

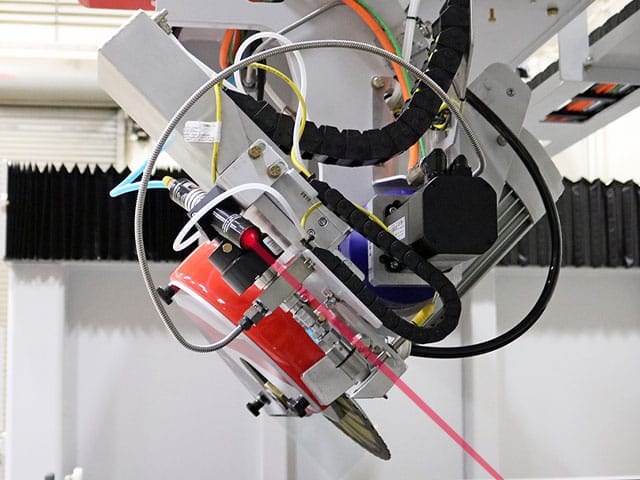

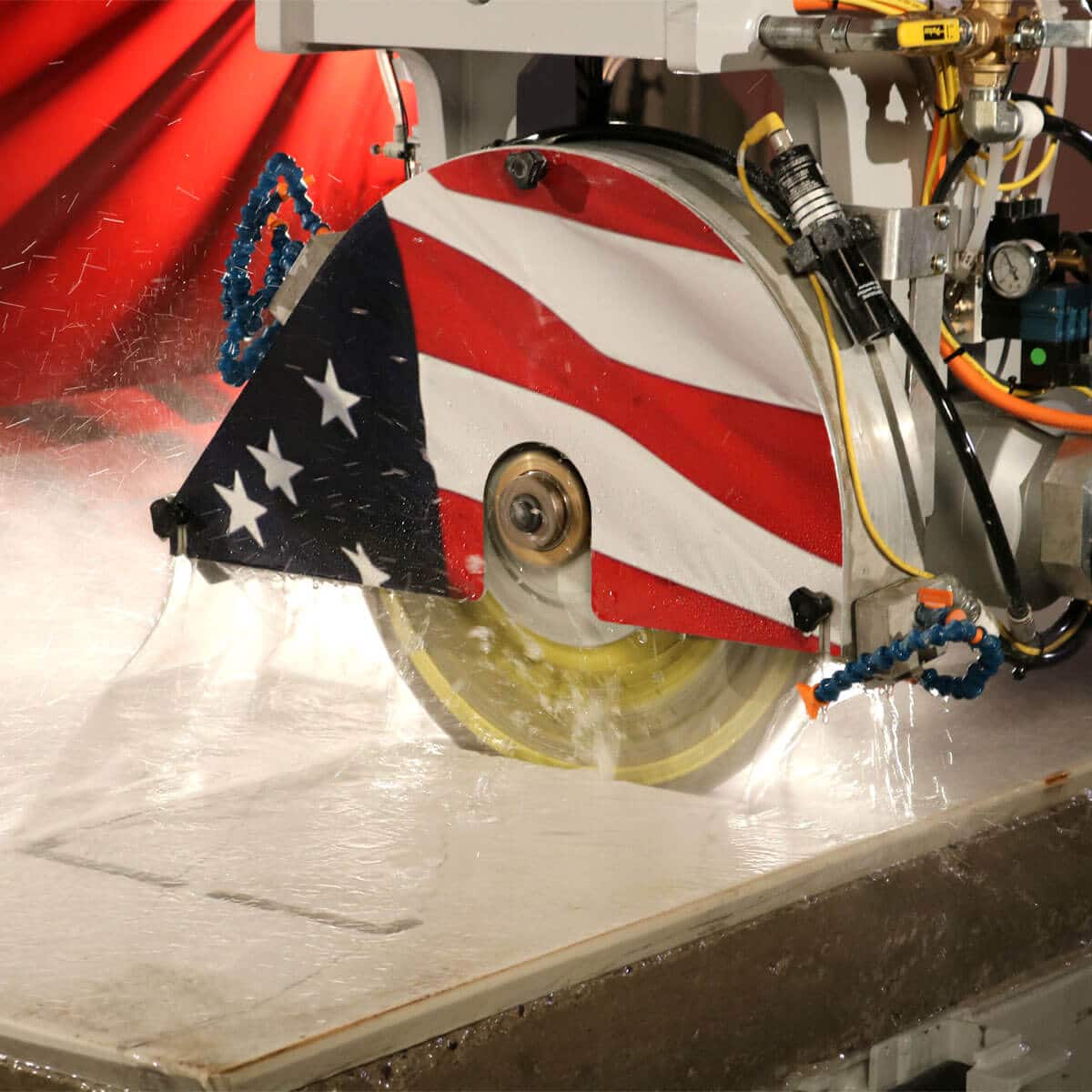

The SABERjet™ XP CNC Sawjet powers up with industry-leading 27 hp saw arbor to make cutting even the hardest materials including ultra-compact surfaces, quartzite, and porcelain materials a snap. This, paired with the new DynaMAX predictive maintenance 50 hp or 60 hp waterjet systems, provides unmatched processing speeds and shop efficiencies.

The SABERjet’s optional VFD (Variable Frequency Drive) increases the saw’s efficiency when cutting ultra-compact surfaces and materials. This VFD option operates at a range of 1200-2500 RPM.

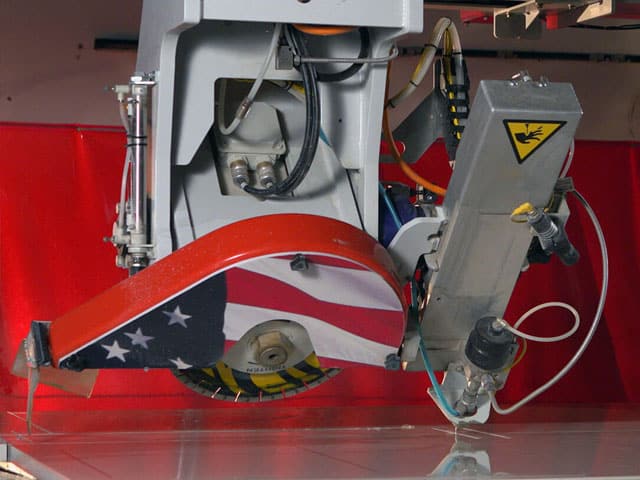

- The MITER Advantage

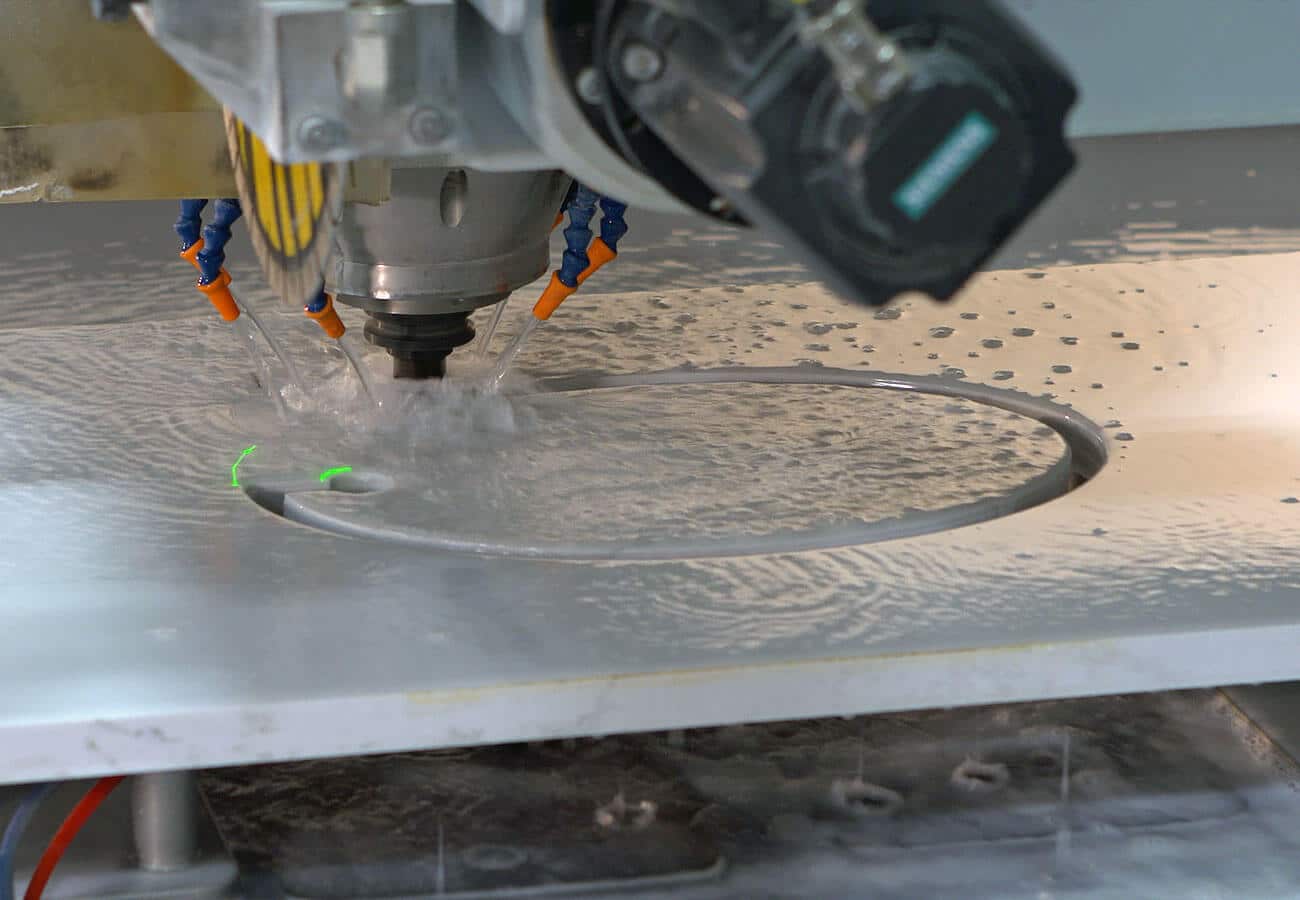

With one of the largest mitering work envelopes in the stone industry – up to 7’x12′ slab coverage – the SABERjet™ XP CNC Sawjet is the mitering sawjet of choice. Reach any miter with its precision mitering blade. Or use its MiterJet feature- mitering performed with the waterjet in addition to the blade. The accuracy of the blade or jet produces flawless miter cuts allowing for tightly nested, clean, accurate parts.

Arc miters? No problem. The SABERjet™ XP quickly and easily performs mitered cuts with its waterjet on non-linear features or sharp 90 degree inside mitered corners in a single pass. Watch the SABERjet™ XP cut a mitered kitchen >

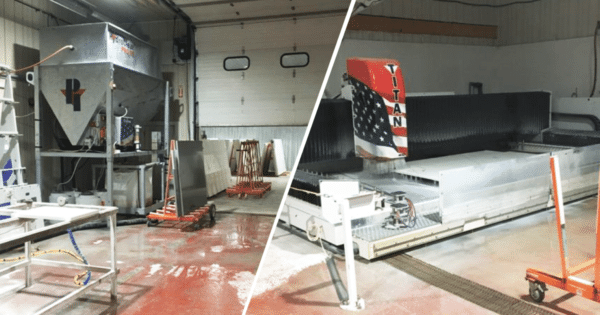

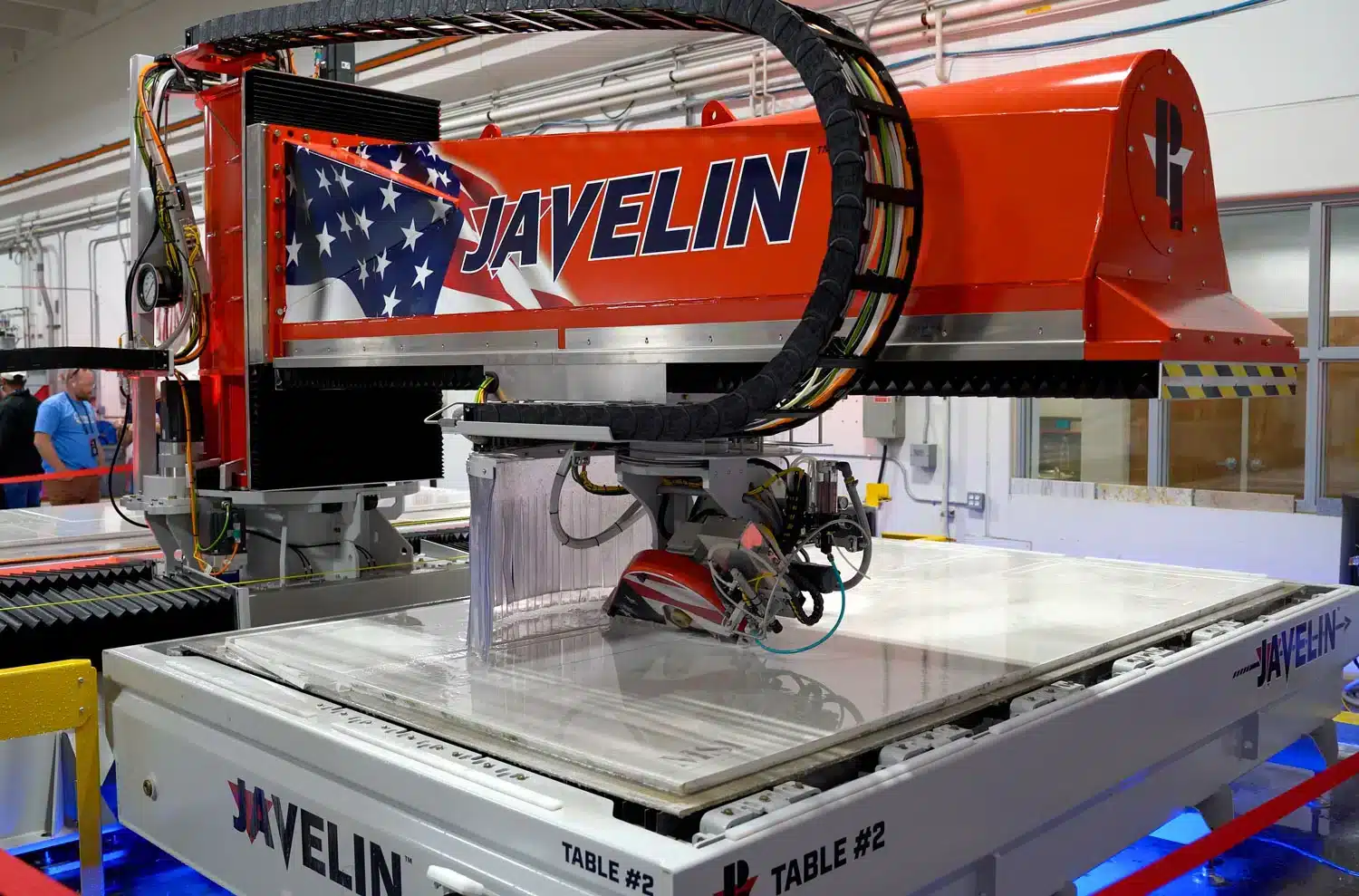

- Two Table Model is Here!

You asked, and we answered…The industry’s leading CNC Sawjet now offers double the production. Never stop cutting with the SABERjet™ XP Two Table Sawjet.

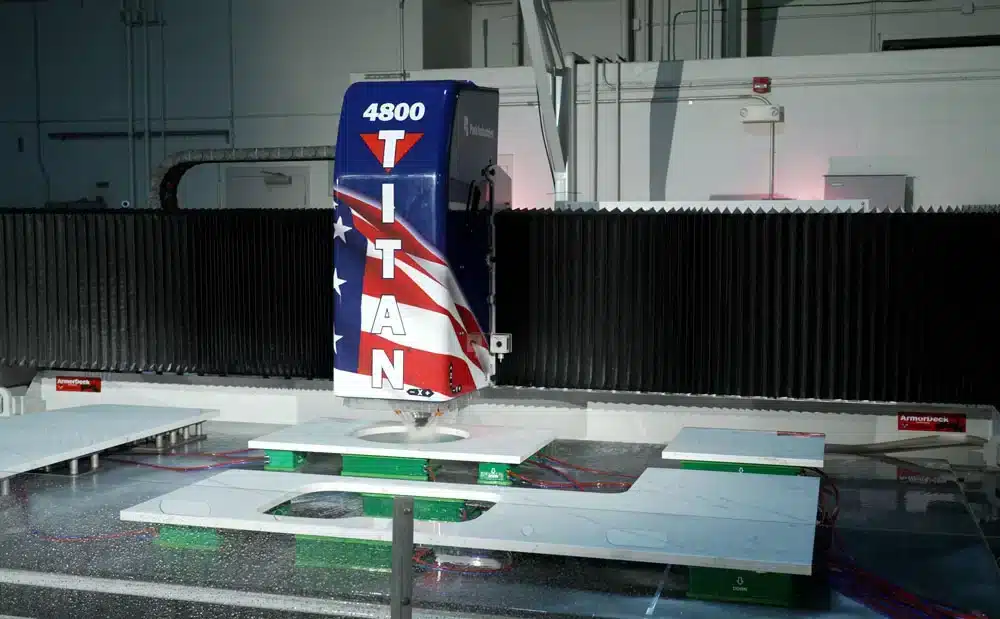

- Compact Design

The small footprint, single-pick, monoblock design of the SABERjet™ XP CNC Sawjet is ideal. True unitized design with no bolt-on extensions resulting in extreme rigidity. The compact sawjet design requires minimal floor space and works well with low ceiling heights – only 11 feet tall.

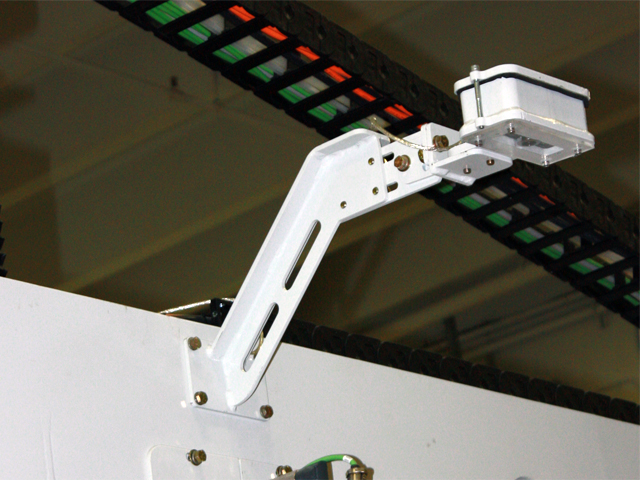

This sawjet design includes high rails and bellow covered ways, protecting the machine from the harsh elements of stone fabrication and maximizing machine uptime/longevity.

- Alphacam programming with exclusive Park EZ™ Buttons

Programming made FAST and SIMPLE! Park EZ™ Buttons, exclusive on Park Industries CNC machinery, make common programming tasks EZ. Paired with Alphacam’s world-class CAD software, use over 40 built-in Park EZ™ buttons to eliminate tedious programming steps and increase your productivity.

With buttons like Auto Tool Path, Ultracompact Automation, and Parametric Shapes – you can save 60% or more of your programming time and clicks!

- Flexible, Operator-Friendly Stone Cutting

Simply take your programmed cut sheet to your SABERjet XP’s touchscreen HMI controller, that runs with the world’s most popular operating system, Windows 10.. Use the barcode scanner and hit go!

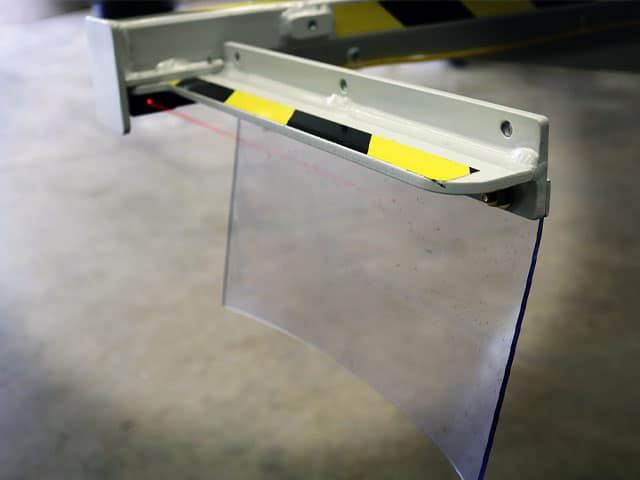

Unique to sawjets, the SABERjet™ XP’s orthogonal cutting mode allows the machine’s blade to cut manually in any direction at any desired angle, with a laser line guide. This cutting style allows for simple manual cuts without generating a program.

Positioning of the machine for manual cutting can be controlled by using manual joysticks on the HMI or a remote pendant, which allows operators to move freely around the sawjet with literally no strings attached.

Specifications

| Select up to 3 models to compare key specs | SABERjet™ XP Single TableView Layout Drawing | |

|---|---|---|

| Arbor Motor | 27 hp | |

| Blade Size | 14" - 16" | |

| Mitering | 0-47° Blade, 0-58° Waterjet | |

| VFD | Yes | |

| RPM's | 1,200-2,500 | |

| 5-Axis Waterjet | Yes | |

| Max Cut Depth | Blade: 3.5" - Waterjet: 4.75" | |

| Max Slab Size (L x W) | 144" x 84" | |

| Cutting Modes | Manual, Full Auto (CNC) | |

| Table / Tank Options | Slab Loader (SL), Ballast, or Standard | |

| Cutting Surface Composition | Rubber Slats (SlabLoader or Ballast), Durock (Standard) | |

| Camera Options | Overhead, SIDE-SHOT, or Pathfinder | |

| Monoblock Design | Yes | |

| Footprint including clearance (L x W x H) | 30'4.75" x 21'10.5" x 10'3.625" | |

| Weight | 20,000 lbs. (SL Tank) |

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.

The miterjet feature is great and helps us efficiently tackle any intricate miter work that we didn’t offer before the SABERjet XP. Now we say bring it on to miter work. We have also been utilizing the bigger horsepower to speed up cuts and tackle any material efficiently.

Yes, I recommend this product.

This is hands down the best saw from the best company in the market! It’s built to last, productive, extremely accurate, and easy to maintain. This machine has truly transformed our workshop.

Yes, I recommend this product.