Vacuum supply water alarm is generated when the vacuum pump water flow switch detects insufficient water flow. A plugged or dirty wire mesh strainer can reduce the water flow which causes the alarm. This procedure illustrates the steps to remove and clean or replace the strainer. Shut-off main water supply Strainer is located on incoming […]

Applies to Water as Part of Stone Fabrication Operations using Park Industries Machinery 1. pH Range: 8.0 – 8.52. Free Chlorine: 3 ppm maximum (If chlorine is used in your facility tomanage bacteria, it is always important to use the proper amount)3. Hardness: 50-300 ppm4. Minimum Total Alkalinity: 100 ppm5. Maximum Suspended Particle Size:Spindle – […]

Dialing the blade to be true with the Machine X, Y & Z axes 1a. Remove the blade, and the blade shroud.1b. Attach the dial indicator to the edge of the water tank. (Ref photo #1). 2a. Once the dial indicator is positioned as in photo #1, set the dial indicator to zero, and move […]

An A Axis Hardware or Software limit switch alarm can be resolved with simply moving the Axis back into its operating range. To clear the alarm, go to the Main Menu and then open the Manual Screen.

Ultra-Compact command will apply predetermined Ramp In and Ramp out feed rate and distance to blade cuts. Ultra-Compact also has a feature to do Tension Band cuts.

LOWER THE NOZZLE ON TABLE AND OPEN THE JET TO BLEED ANY PRESSURE FROM THE SYSTEM BEFORE WORKING ON THE JET ASSEMBLY FOLLOW LOCK OUT TAG OUT PROCEDURES If you encounter leaking ,shut down the jet (intensifier ) then tighten again . (The idea is to tighten very slowly until the leak stops) You may […]

This procedure is how to install a metal goretrac on the double table fusion. Verify that the gauge up top of the machine is at 0 this verifies that there is no residual pressure in the lines. Verify that there is no residual pressure in the hp lines . The big gauge up top of […]

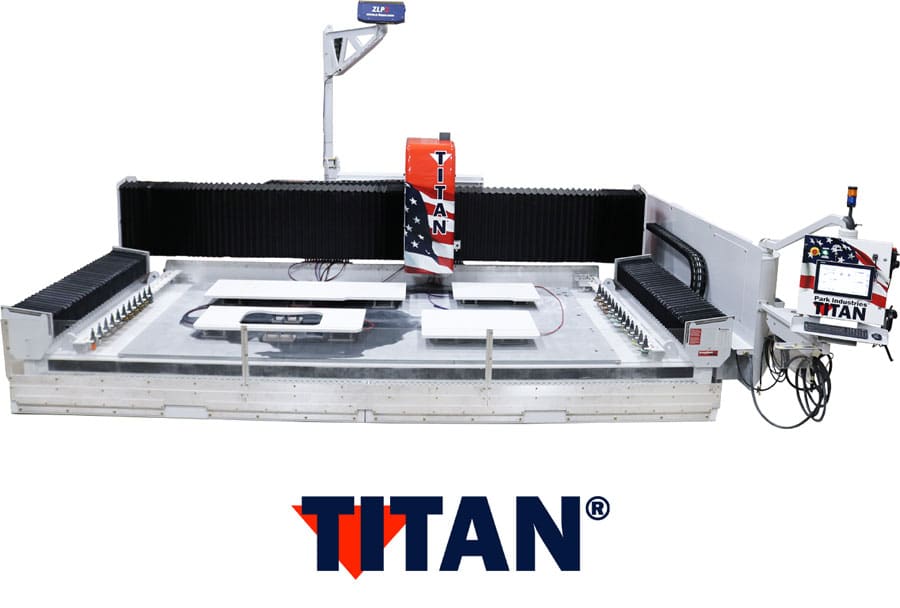

Guide shows how to change the THK bearings on the ‘Y’ axis of the Titan and Destiny. Loosen 4 bolts holding the THK bearing from top side of gantry just above bearing location. There are 4 bolts per bearing (8 per side). Loosen completely but do not remove the bolts from the holes. Also loosen […]

How to assemble a High Pressure Swivel 70008044-2 Kit. You will need the following: Large adjustable wrench 1 & 1/8″ open or box end wrench Isopropyl alcohol Lithium grease Blue Goop O-Ring lube O-Ring pick or small flat blade screw driver Seal Removal Tool Bench Vise Hammer Arbor press – if available 0.575″ gauge pin […]

- Programming

- Software Support

If you lost the Quick Access Tool bar you an import it back in.

These videos show how to install and remove the new Quickset gripper set assembly # 96381 this new style gripper assembly will only work with Armour Shield Protected drawbars. verify you have this first. see image below.

Using the different features of the CNC Router Pendant the side button must be pressed to “Enable” the keypad to achieve machine movement When the enable button is pressed and a key pad arrow is pressed the cross travel will move in the respective direction To use the Incremental Movement option on the Titan pendant, […]

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.